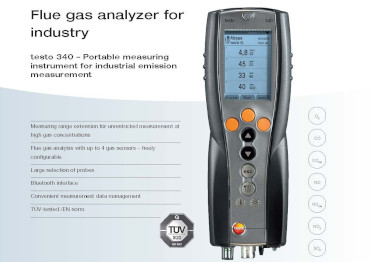

The GORE SO2 Control System is a flue gas desulphurization system (FGD) which allows plants to comply with SO2 emission standards without requiring any reagent...

To determine if a proposed project is technically, economically, and environmentally viable. Focus Preliminary analysis, identifying potential risks and opportunities, and evaluating the project's overall practicality ...

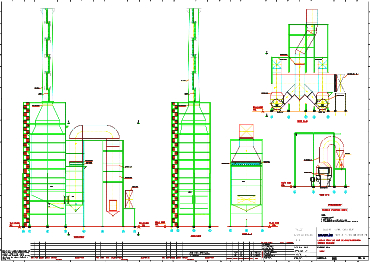

FEED aims to ensure a project is well-defined and understood before detailed engineering, procurement, and construction (EPC) phases begin. FEED is often considered the third and final stage of the Front-End Loading (FEL) process ...

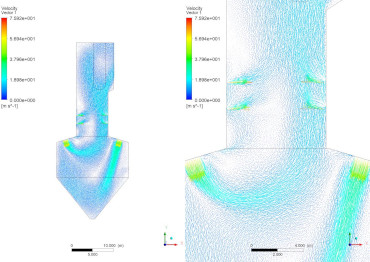

A Cold Air Velocity Test (CAVT) in a boiler is a method used to predict flue gas flow patterns, identify areas of high velocity, and assess potential erosion risks, especially in the second pass of the boiler...

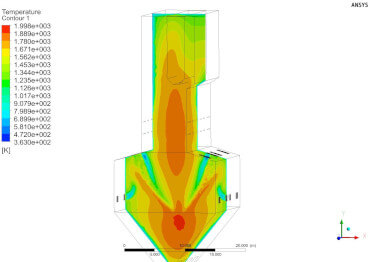

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and data structures to analyze and solve problems involving fluid flows, simulating fluid behavior and heat transfer using computer-based simulations...

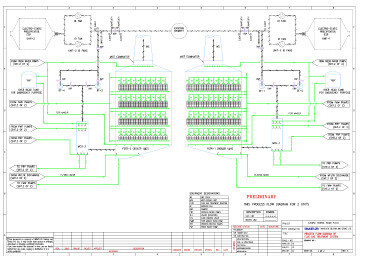

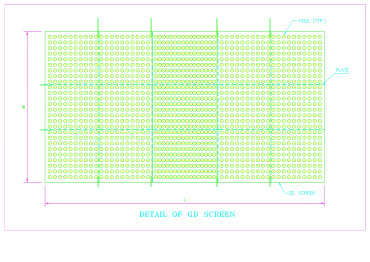

In the context of Electrostatic Precipitators (ESPs), a "GD screen test" refers to a Gas Distribution (GD) test, which assesses the uniformity of gas flow across the ESP's cross-section to ensure effective particulate collection. A uniform gas distribution is...

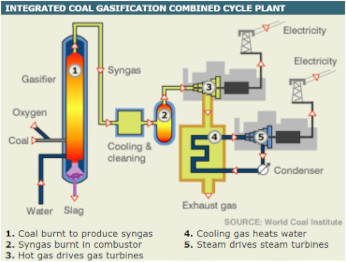

A fuel change study in the power sector examines the potential for switching from one fuel source (like coal) to another (like natural gas or renewables) to improve efficiency, reduce emissions, and enhance energy security...

Boiler combustion optimization aims to maximize efficiency and minimize emissions by optimizing fuel-air ratios, burner settings, and combustion conditions. This involves techniques like excess air control, stack gas temperature reduction, and...

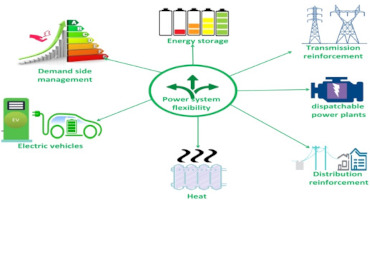

In power systems, "operation flexibility with frequency control and two shifting" refers to the ability to adjust power generation and consumption to maintain frequency stability and accommodate changing...

Power plant life extension involves extending the operational lifespan of existing power plants beyond their original design life, aiming to maximize electricity generation and resource utilization while ensuring safety and environmental compliance...

Electrostatic Precipitators (ESPs): Charge particles and then use electric fields to attract them to collecting plates, removing them from the air...

Key Aspects of O&M Services: Daily Operations: Ensuring systems are operating correctly and efficiently, including monitoring performance and addressing issues as they arise...

Construction, Installation, and Commissioning (CIC) services encompass a wide range of activities involved in building, assembling, and testing various structures, equipment, and systems...

Power plant spares refer to the replacement parts needed for maintaining and repairing power plants. These spares can include various components, such as turbine blades, boiler parts, and other machinery parts...